Chocolate Aroma: Factors, Importance, And Analysis.

Cover image is taken by Geoseph Domenichiello. The following is a summary of the stated research mentioned above. The content summarized here, including the figures and tables, all belong to the researchers (unless otherwise indicated). The summary attempts to stay as close to to the original paper as much as possible with some adjustments in regards to jargon, length, or to focus on bean to bar aspects

Introduction

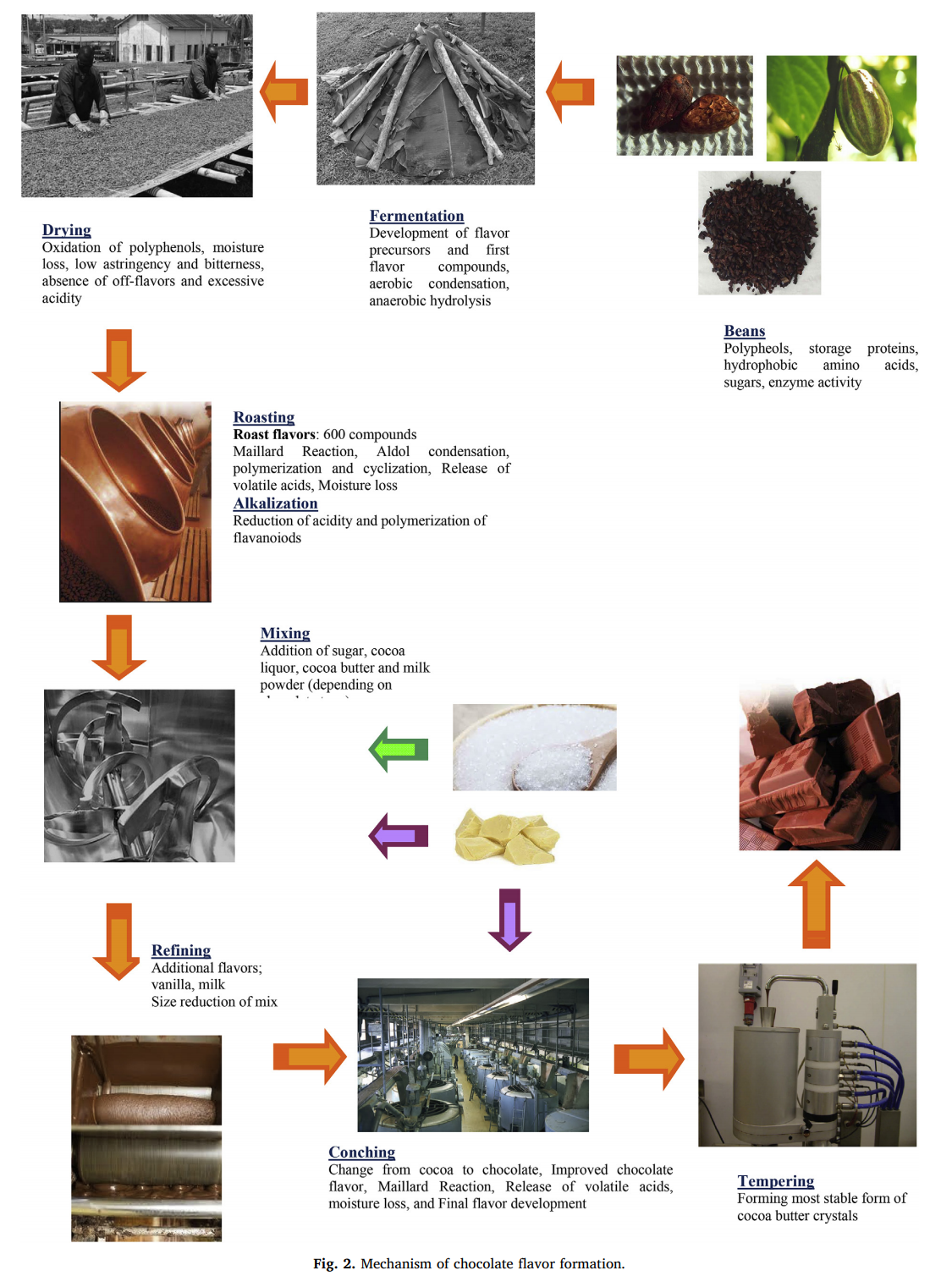

Chocolate has a unique sensory experience associated with the way it melts in the mouth as well as odour and taste properties. The factors responsible for chocolate flavour are:

Cocoa cultivation (genetic origin)

Post harvest treatment (fermentation and drying)

Chocolate processing (roasting, conching)

Type and amount of ingredients (cocoa, sugar, fat, milk powder, emulsifiers)

The evaluation of aroma in chocolate is a complex and long studied aspect within the food industry. Being able to evaluate the different sensory attributes of chocolate can help asses consumer preferences.

In this study, factors infecting aroma of chocolate and methods performed to determine them are provided.

Aromatic Compounds Related With Chocolate

Main Aromatic Components In Chocolate

There are over 600 volatile components in cocoa and chocolate products which make up the “flavour” of chocolate. These components can be classified as the following groups of aromas: aldehydes, pyrazines, alcohols, carboxylic acids, esters, ketones, furans, amines, amides, acids, phenols, terpenes, and hydrocarbons.

A few very specific aromas (see Figure 1), which are key to impacting the overall chocolate flavour include:

3-methylbutanal (chocolate, malty)

2-methylpropanal (chocolate, malty)

phenylacetaldehyde (rosy)

tetramethylpyrazine (nutty)

2-ethyl-3,5-dimethylpyrazine (potato-like, popcorn)

2-acetyl-1-pyrroline (popcorn-like)

trimethylpyrazine (nutty, earthy)

3-methylbutanoic acid (sweaty, cheesy)

acetic acid (sour, harsh)

vanillin (vanilla)

2-methylbutanal (chocolate)

3,5-diethyl-2-methylpyrazine (chocolate, cocoa, roasted, rum)

furaneol (caramel-like)

It’s important to note that different odors have different odor thresholds. This means some require a very small amount for our bodies to detect them, and some require more. The specific compound and its amount will determine the chocolate’s final flavour.

Essentially, the process of chocolate making from harvest to roasting to final product is done to optimize the desirable aromas and decrease the undesirable aromas.

Cocoa Originated Aroma Precursors

These aromas mentioned above come mostly from the cacao and chocolate processing. However, the components and percentage of each ingredient is also important.

The main aroma precursors (compounds which help build the aromas) include mostly:

short chain peptides (coming from protein molecules)

free amino acids

reducing sugars

cyanidin-3-galactoside

These precursors are developed mainly during fermentation, which break down larger molecules such as proteins and carbohydrates, into smaller ones listed above, which will interact during roasting to form aroma compounds.

The various types of these compounds to exist, and how much, will depend greatly on the variety or genetics of the cacao. There are also distinct flavour characteristics of the same variety in different geographic origins.

Effects Of Ingredients On Aroma Development

Depending on whether the chocolate is dark chocolate or milk chocolate, high quality or lower quality, the ingredients will vary.

The Effect Of Cocoa Origin On Aroma

The main ingredient! Raw cocoa generally has a very unpleasant taste and aroma. What we know as the flavour of cocoa is achieved after fermenting, drying, and roasting it. Like comparing the flavour of a raw onion to caramelized onions, or raw potatoes to fried chips. It’s a different world of flavour.

Raw cocoa beans have a bitter notes which come predominately from the main alkaloids found in the cocoa beans:

methylxanthines

caffeine

theobromine

theophylline

The amount of these alkaloids depends on the variety. These alkaloids decrease after fermentation, which is why there is a reduction in bitterness after fermentation.

2.3.2. Milk Fat

Milk fat is found in milk chocolate product. It has been stated to help against fat bloom in tempered chocolate, and also softens the chocolate (due to fat eutectics). It helps slow down the transformation from form V crystals to form VI crystals which produces that white chalky look on the surface of old chocolate.

Milk fat also imparts flavour onto the chocolate. When milk fat is heated, flavour components such as methyl ketones and lactones are formed. The heat generated during the chocolate processing isn’t usually sufficient to form these components.

Lipase (found in fresh milk) can hydrolyze the triglycerides (the fats) and produce favorable fatty acids such as caproic, butyric, and capric acids, which give milk chocolate its creamy and buttery flavour. Keep in mind, milk lipase is inactivated during pasteurization. As well, the rate of lipolysis in milk fat should be controlled to prevent a cheesy flavour.

Milk Proteins

Milk proteins can influence chocolate flavour, chocolate texture, and the flow properties of liquid chocolate. In the presence of heat (roasting) and water (moisture in the unroasted cocoa bean) these proteins can contribute to flavour (aroma compounds) via the Maillard reaction.

Sugar

Other than cacao, sugar is the other main ingredient in chocolate. It’s used to overcome bitterness and astringent flavours. It also impacts the overall flavour profile of the chocolate, and rheological characteristics (how it flows, how viscous or liquid it is) of liquid chocolate.

If the sugar is ground together with the chocolate, the aromas from the chocolate will adhere to the sugar surface and give a more intense flavour. Aroma molecules will adsorb (different from absorb, where adsorb the aromas attach to the surface of the sugar crystals rather than get drawn into the crystal) to the sugar. Sugars are also important to reactions of the Maillard reaction during conching.

Amorphous vs crystalline sugar and bloom:

Bricknell and Hartel (1998) studied how amorphous (think lollipop) vs crystalline sugar (think table sugar) impacted bloom formation in chocolate. Under a microscope, one can see crystalline sugar has very sharp edges, and amorphous have smooth spherical particles. The rounded surface of amorphous sugar allowed for tighter packing of the sugar within the chocolate. Due to less space to move around, the migration of any liquid cocoa butter (TAG molecules) was slowed down, and reduced sugar bloom in chocolate.

Sugar and lecithin could also work together to to slow down the process of sugar bloom. The lecithin sits on the sugar molecules, and impacts the migration/movement of liquid cocoa butter through the chocolate by altering the recrystallization process at the surface.

Low calorie sugars:

These impact the aroma profile of chocolate. Rebaudioside A has the most acceptable flavour and is the most stable of the steviol glycosides. Fibers such as inulin have no “off flavours”.

Palm sap sugar:

This will create a distinct flavour within chocolate. Chocolates made with palm sugar blends resulted in chocolate with higher levels of volatiles than chocolates made with sucrose. The additional volatiles were:

2,5-dimethylpyrazine

2,6-dimethylpyrazine

2-ethyl-6-methylprazine

methylpyrazine

2,3,5-trimethylpyrazine

2-pyrrolidinone

alkyl furan

2(3H)-dihydrofuranone

2-furan methanol

2,3-butanediol

phenylethyl alcohol

2-acetylphyrrole

acetic acid

When in the amorphous phase, the more aroma volatiles were trapped, producing a higher concentration of aroma volatiles in the sugar, and therefore a higher concentration overall in the chocolate.

Fermentation

This develops precursors necessary for chocolate aroma later down the line. During fermentation, the cocoa beans and their fruit are placed in heaps or wooden boxes and allowed to ferment for 5-6 days. Usually the fermentation is spontaneous with local fungi, yeasts, and bacteria. There are many sources of yeast and bacteria inoculation including:

The farmer’s hands

Equipment (knives)

Fermenting boxes

Surfaces

Dry pulp

Fermenting trays

Plantain leaves used to cover the fermenting masses

Due the anaerobic conditions of the first phase, alcoholic fermentation is the first to begin thanks to the yeasts present and sugars from the pulp of the cacao fruit. This produced carbon dioxide. Yeasts dominate the first 24-36 hours of the fermentation. However, as they dominate, so does the pH level rise, and as it does, it will begin to inhibit yeast formation.

The second phase is termed the oxidative condensation phase, and occurs under aerobic conditions (with oxygen) and set off by the lactic acid bacteria. The mass temperature by this point will rise to about 45*C and encourage lactic acid bacteria growth.

Fermentation is important to both flavour and colour of the cocoa beans. A major purpose is to reduce bitterness in the unfermented cacao bean. During fermentation, enzymes are released that break down carbohydrates and proteins into simpler molecules (simple sugars, peptides, and amino acids) that will be used later for aroma molecule formation.

Different fermentation methods produce different flavours in the cacao beans. Box fermentation allows for more aeration and aerobic bacteria (Acetobacter) produce the acetic acid. Carboxylic acids produce off-flavour notes such as butter, rancid, and hammy. The esters generated here present a fruity flavour, but this is often loss during the high temperatures of roasting. The temperature and level of acidity are factors that determine the reaction rates.

Proteins

Proteins are degraded during fermentation by the enzyme proteases. Well fermented beans can be differentiated by under-fermented ones by the higher amounts of oligopeptides. Therefore, one can use the peptide profile of the bean to indicate the degree of fermentation (Kumari et al., 2018).

Free amino acids and hydrophobic peptides are formed due to these enzymes, and later will be utilized during roasting. Cocoa beans from different geographic regions and genetic origins produced chocolate with different qualities.

The proteins in cocoa beans play a critical role in flavour development. The activity of aspartic endoprotease and carboxypeptidase (enzymes) break down the proteins in the seeds to smaller precursor molecules. Under optimal conditions (pH 5.2) hydrophilic peptides and hydrophobic free amino acids are produced, and the mixture of these two is able to produce the unique cocoa flavour during roasting. Free amino acids such as:

leucine

alanine

phenylalanine

tyrosine

which are found in fermented cocoa beans react with reducing sugars (fructose and glucose) druing the Maillard reaction which occurs at high heat.

Sugars

Raw cocoa beans contain free sugars such as:

sucrose

glucose

galactose

fructose

sorbose

arabinose

inositol

mannitol

xylose

and polysaccharides such as:

starch

cellulose

pectins

pentosans

mucilage

During fermentation, sucrose is broken down to glucose and fructose. As well, the concentration of methylxanthines decreases (about 30%) after 72 hours of fermentation and leads to a reduction in bitterness.

Polyphenols are what make chocolate astringent or bitter, but also contribute to the green and fruity flavours present. During the first phase of fermentation, polyphenols are hydrolyzed and oxidized, reducing bitterness and astringency. During the second phase of fermentation, oxidation of protein-polyphenol complexes and carbonyl-amino condensation reduces astringency. The reactions between proteins/peptides with polyphenols give cocoa its brown colour. Usually, polyphenol levels decrease with fermentation, but there were cases noted that their levels didn’t change or were even increased. The increase could be due to polymerization reactions (Rusconi & Conti, 2010).

Hydrophobic amino acids exposed to the Strecker degradation produced aldehydes and aminoketones, which later will develop into pyrazines (probably the most important category of aroma molecules in chocolate).

Other Results of Fermentation

The main flavour compounds produced during fermentation include:

ethyl-2-methylbutanoate

tetra-methylpyrazine

other pyrazines

Theobromine, caffeine, and diketopiperizines (formed during roasting as proteins denature) contribute to bitter notes.

Flavour precursors derived from amino acids liberated through fermentations include:

3-methylbutanol

phenylactaldehyde

2-ethyl-3,5-dimethyl

2-methyl-3-(methyldithio) furan

2,3-diethyl-5-methylpyrazine

If cacao is under fermented, it will have less chocolate flavour. If cacao is over fermented, it will have a hammy flavour.

It has been shown that as fermentation progresses, acids and esters increase while alcohols, aldehydes, and ketones decreased (Da Veiga Moreira et al., 2018).

Artificial Fermentation Methods & Starter Cultures

Artificial, or non-spontaneous/traditional, methods of fermenting may result in cacao with different qualities and aroma profiles.

Specific yeast strains could generate a specific desirable flavour profile (Engeseth & Pangan, 2018). Some strains to inoculate the fermentation heap can include Pichia kluyveri and Kluyveromyces marxianus.

Fermentation Methods

The fermentation method had the greatest impact on volatile aroma profile. Starter cultures also affected the aroma profile, but not enough that it could alter the consumer perception of the chocolates. That said, the activity of microorganisms such as Bacillus subtilis, B. megatrium could produce the formation of pyrazine compounds (Khairy et al., 2018).

Using two fermentation methods was shown to impact cocoa and chocolate flavour. Owusu et al. (2012) looked at the impact of using two fermentation techniques, heap and tray, on cacao flavour and aroma profile. These two methods had some effect on the type and number aroma volatiles produced as well as their concentrations with in the cacao. Tray fermentation lead to a cacao that was more sour (from higher levels of acetic acid).

Aeration

Increased oxygen transfer (by stirring or moving from one box to another) to the fermenting cacao promoted amino acid formation (aroma precursors). The size of the fermentation mass also impacted oxygen transfer. A very large cocoa seed mass leads to less aeration, less microbial activity, and lower amounts of flavour precursors. Too small of a fermentation mass also had similar impacts due to losing too much heat during aeration, less microbial activity, and again less flavour precursors. The right size of fermentation mass that allows for aeration while maintaining good temperature is important for good flavour.

Drying

Sun Drying

This may result in better chocolate flavour and less off-flavours. The cacao beans are dried until they are below 8% moisture. The downside to sun drying is that it is harder to control, especially in regions that get long rainy seasons. The seeds can also easily be contaminated by animals or chemicals used on the farm being exposed out in the open air.

Artificial Drying

Often wooden fires are used to funnel heat in the direction of the beans which often lay on trays. However, this often imparts smoky or hammy off flavours to the cacao especially if the smoke isn’t controlled well. As well, artificial drying in this manner also may harden the husk or testa of the seed, and trap in much acetic acid and other acids which are supposed to evaporate during the drying process. Quality cacao and chocolate for that matter should not be very acidic.

Flavours

Even during drying, new flavours are formed within the seed due to polyphenol oxidizing reactions.

Well dried cacao have a nice brown colour, and have less astringency, bitterness, and off-flavours. Drying also reduces the concentration of volatile fatty acids (propionic, acetic, butyric, and isobutryic acids) which may contribute to off flavours.

Drying also allows for the production of some furanones and pyrones due to degradation of monosaccharides. These are produced via a reaction of free amino acids and glucose. However, if the cacao is alkalized, these compounds can be destroyed.

Amadori compounds are also formed in dried unroasted cacao. These compounds will eventually lead to producing to cocoa-like flavour compounds.

Roasting

Roasting develops the flavour of the cocoa in profound ways by utilizing the precursor compounds created during fermentation. Roasting will reduce acidity (that was built up during fermentation). Many of the precursor compounds include:

amino acids

leucine

alanine

phenylalanine

tyrosine

fructose

glucose

These compounds participate in the Maillard reaction which occurs in the presence of heat and water (moisture from the cocoa bean). Although roasting will reduce some volatile acids such as acetic acid, it will not really have an impact on lactic, tartaric, succinic, citric, and oxalic acid.

Unroasted cacao often tends to taste bitter, astringent, flat, sour, or sometimes musty.

Cocoa beans are usually roasted around 120*C to 140*C. Temperatures above 150*C or roasted for too long will result in over-roasted beans with burnt, bitter, and coffee-like flavours.

Both time and temperature really impact how the precursors mentioned above are utilized during roasting. It’s been reported (Ziegleder, 1991) that 25% of free amino acids and 70% of the reducing sugars (glucose and fructose) are used up during this Maillard reaction.

The reactions begin with an amino acid, peptide, or protein combined with a reducing sugar. This creates di-carbonyl components.

Pyrazines

Di-merization of ketoamines into di-hydropyrazines with a subsequent oxidation form pyrazines. Pyrazines are volatile aromas very important to the overall chocolate flavour. It is during the Maillard and Strecker reactions that most pyrazines are formed, although some are formed during drying. Pyrazines are volatile heterocyclic nitrogen containing compounds. They form the typical cocoa and cocoa butter flavours we are familiar with. The variety of the cacao beans also determines the total concentration of pyrazines. Very high temperature and prolonged time can negatively impact the concentration of pyrazines. That said, some studies have shown that pyrazines may increase with extended roasting time (Khairy et al., 2018).

Aldehydes

Aldehydes are another important family of aroma compounds, and formed via the Stracker degradation of amino acids. Again, high temperatures and long roasting times may decrease the content of aldehydes. They may contribute flowery notes to the cocoa. Aldehydes and ketones together may offer up malty, chocolate, flowery, and sweet notes. Aldehydes can also contribute to the formation of some pyrazines.

Polyphenols

Polyphenols may present fruity flavours. High temperatures during roasting influence levels of polyphenols, and can reduce total polyphenol content. However, this reduction could be the polymerization of low molecular weight polyphenol compounds with one another. Temperatures below 140*C can maintain levels of polyphenols. Alkalization reduces polyphenol levels a great deal because polymerization and oxidation of polyphenols occur in alkaline environments (Giacometti et al., 2015).

Other Compounds

Proteins, peptides, polyphenols, vitamins, lips, and other oxidation products can take part in the roasting and impact the flavour of the cacao.

Cocoa can be roasted as whole beans, nibs, or liquid cocoa mass. The advantage of roasting nibs or liquid cocoa mass is that the smaller uniform particles allow for a more controlled and even roast, and reduce the roasting time, while also helping remove some of the excess acetic acid that is now exposed. Acetic acid is mostly unchanged in whole bean roasting, but considerably reduced in liquor roasting.

Roasting time for whole beans can be up to 30 minutes, nibs for 12 minutes, and liquor for around 2 minutes.

Roasting pre-treatment

Some have stated that one can pre-treat unroasted cocoa nibs or liquor with water to increase flavour development. A pre-treatment of raw cocoa nibs with 15% water for 15 minutes at 40*C, followed by drying at 98*C to 3.5% water content lead to a more intense cocoa taste and increased level of roast flavour compounds compared to cocoa that wasn’t pre-treated. The pre-treatment allowed for the consumption of more amino acids and reducing sugars, and an increase in the level of Amadori compounds. It is likely that the added water dissolved the amino acids and sugars and helped encourage their reaction together.

Marker Compounds Of Cocoa

Pyrazines are the main volatiles that make up the cocoa flavour, and so can be a good marker to determine the flavour quality of the chocolate. Many of them originate from the Maillard reaction, mostly during the roasting stage.

Pyrazine concentrations can depend on weather conditions of growing cacao, the variety of cacao, ripeness when picked, and chocolate processing (Da Veiga Moreira et al., 2018). Well-fermented cocoa from Ghana has higher levels of pyrazines (698 ug/100g) than Mexican cocoa (142 ug/100g) (Afoakwa et al., 2008). The criollo cultivar contains more pyrazines than the Nacional/Arriba cultivar which contains very low levels.

Tetramethylpyrazine (Roasted, Green, Coffee, Cocoa) reaches high concentrations (7mg/kg) at medium roasting conditions, but is mostly formed during fermentation.

Odor Thresholds

Different aroma molecules require different thresholds in order for humans to notice them. For instance, the threshold for pyrazines can range from 10 mg to 0.000002 mg/kg, a very wide range.

Relation Between Chocolate Processing And Chocolate Aroma

The process of making chocolate (roasting, refining, etc) all have a massive impact on the final flavour of the chocolate. The authors discuss conventional and alternative processing techniques and their impact on flavour formation.

Importance of Refining And Particle Size

Ingredients for chocolate (cocoa, sugar, etc.) need to be ground down to reduce particle size. They can be ground together, or ground separately and then mixed later. Grinding them together may allow for better flavour production. When grinding the cacao beans and sugar together, the sugar particles will pick up the aromas given off by the cocoa particles.

Optimum particle size will influence chocolate texture, flavour, and flow of liquid chocolate (important when tempering it). The particle size distribution of the cocoa may impact the defining flavour characteristics of the chocolate. Chocolate with similar ingredients but different particle size may have different flavour and quality characteristics.

The sensory properties of the cocoa are sensed earlier after consuming, than sugar or milk powder (in the case of milk chocolate). It is suggested that the smaller the particle size of sugar, the more sweet the chocolate tastes. Smaller particles of sugar can dissolve more quickly than larger ones (which also offer less surface area to be exposed to). However, this was observed in chocolate brownies, not chocolate bars (Richardson et al., 2018).

Zeigler et al. (2001) and their results illustrated that as the average particle size of chocolate got finer, the higher the overall satisfaction from the chocolate’s melt and texture. They also found the flavour of chocolate’s with finer particle sizes persisted longer than chocolate’s whose particle size were larger.

Ball Mill vs Roller Grinding

There are two different types of grinding : roller and ball mill grinding. Grinding transforms sucrose from a rigid crystalline to a more round amorphous state. Ball mill is more efficient, and can mix and grind at the same time. However, Ball milling isn’t as good at roller milling in regards to reducing moisture and acidity. Moisture and acidity are intended to be reduced a great deal before the product is finished. Too much moisture will result in particle agglomeration, and prevent the particle sizes from getting small enough. Too much moisture also dissolves the sugar, and creates sticky patches on the surface of sugar and leads to agglomeration. Ball mill grinding can lead to greater chance of agglomeration.

Afoakwa, Paterson, Fowler, and Ryan (2009a) found that increased particle size resulted in less aroma being released from the chocolate due to increase in matrix retention via structural, rheological and textural differences.

Non-Fat Particles Size on Fat Bloom

The smaller the particle size also impacted fat bloom, where smaller particle size increased migration rates (of liquid cocoa butter) and therefore accelerated fat bloom. Dahlenborg, Millqvist-Fureby, and Bergenstahl (2015) looked at the impact of particle size on oil migration based on samples with particle size of either 15 um, 22 um, or 40 um. The sample with 15 um particle size had the highest rate of fat bloom, followed by 22 um, with 40 um being the lowest. However, a study by Choi, McCarthy, McCarthy, and Kim (2007) found the opposite to be true.

It is believed that the small particle sizes of non-fat particles allow for more surface area. More surface area creates fat passage ways for which the liquid fats can more easily migrate through, as opposed to being blocked by larger particles.

Flavour Development During Conching

Conching conditions depend on time, temperature, and technique (type of equipment or shearing force). During conching a high amount of moisture and phenols are removed (oxidation of tannins). Up to 80% reduction in volatile phenols are observed in the first few hours of conching. The viscosity and colour are also impacted by conching. The viscosity likely impacted from the loss of moisture.

Oxidations and enzymatic mechanism causes the polyphenols to form a irreversible complex with the amino acids, peptides, and proteins (Dimick & Hoskin, 1999). This results in the removal of flavour volatiles and a reduction in astringency and mellowing of the overall chocolate flavour.

Conching also develops new aromas. Amadori compounds that were created during drying or roasting are reduced through evaporation or chemical reactions during conching. n milk chocolate, the lactose may caramelize and interact with the Maillard reaction. Furaneol and maltol are formed according to Schnermann and Schieberle (1997). Braga et al. (2018) stated that some compounds not detected in the nibs or liquor before conching were identified after in the final chocolate, solidifying the idea that conching does develop new aroma compounds.

As well, off-flavours tend to diminish via evaporation during conching such as:

3-methyl-butanal (cheesy, rancid)

hexanal (green)

dimethyl disulphide (cabbage, sulfur)

Physical Changes

Flavour molecules can move between different ingredients during conching. At the beginning of conching, the flavours are within the cocoa solids and cocoa butter, but eventually transfer onto the sugar. This results in a more uniform flavour and less sweet (Beckett, 2008).

Although conching can create new flavours and reduce off-flavours, conching for too long will result in a loss of even desirable flavours via evaporation (Fisher, Abubaker, Hasselbarth, & Ulrich, 2010; Owusu et al., 2012).

Fischer et al. (2010) found that there was a difference in aroma transference between fat and water-soluble particles. Those aromas concentrated in the fat during conching changed, while aromas concentrated in the sugars and cocoa solids remained stable.

Pyrazine and pyrrole increases during conching of chocolate, but some pyrazines may decrease with prolonged conching (Fischer et al., 2010). Owusu et al. (2012) reported that shorter conching times resulted in higher amounts of:

dimethyl trisulfide (an off flavour)

2,5-dimethylpyrazine (rum, cocoa, roasted nut)

2,3,4,5-tetramethylpyrazine (nutty, chocolate, coffee)

linalool (flowery)

The Maillard reaction is complex, but occurs in 3 main phases. The first involves forming substances that will react later. Some of these substances are reversible. The second phase, reactive carbonyl components are formed, which determine colour and flavour development in the final stage. The final stages involve Cyclization and aldol condensation which results in aroma volatiles such as pyrazines, as well as polymerization to form melanoidin pigments.

“Coarse Conching” technique

This was applied by Bolenz and Lipp in 2011. This process can help remove more moisture and undesirable aromas. Normally, grinding is done first, and then conching to finish off the chocolate. Here, it is the reverse. The raw ingredients and coarse sugar are dried and conched. Water is reduced to less than 0.6%. The taste of the coarse conched chocolate was more intense and less sweet than the chocolate made from the more conventional roller refiner and then conch. There was also an improvement with mouthfeel. No major differences were observed related to nutty flavour, stickiness, melting, or hardness.

Tempering And Aroma

The cocoa butter has a huge influence on the flavour and texture of the chocolate, and so it’s essential to know how to obtain the required fat structure via tempering.

Tempering mainly has an impact on chocolate texture. This texture will impact how it is received in the mouth, oral behaviour, but also impact stimuli release including aroma (Saint-Eve et al., 2011).

Chocolate that is tempered well has a very uniform structure. When it melts in the mouth, the 3D structure of this fat allows it to spread out all the material within the suspension uniformly. The stable polymorphic form of beta 5 crystals acts like a net to preserve all the ingredients in the suspension. The saliva will dissolve it and release the aroma compounds from the suspension.

The flavour attributes of chocolate are dependent on the fat phase composition, and fat bloom impacts the appearance attributes. Interestingly, due to how fat bloom is the migration of fats, this migration can also lead to a loss of some oil soluble aroma compounds.

Evaluation Of Aromatic Compounds

The aroma profile of chocolate needs to be checked through the chocolate making process in order to produce the desired overall flavour profile.

Instrumental Determination Of Aromatic Compounds

One can use instruments to determine which aromas exist and at what concentrations.

One uses static headspace (HS) aroma isolation with gas chromatography (GC). This extracts the aromas in the headspace above the chocolate via a vial, and are then to the gas chromatography in order to be identified. The other uses aroma extractions and distillations with mass spectrometry (MS) or olfactometry. Both methods have advantages and disadvantages.

The most challenging part of quantifying aroma is achieving the complete aroma profile. Researchers must have a precise aroma isolate, but to this day there is no adequate isolation method to produce an exact analytical profile. The best way today is to combine a few analytical methods of aroma isolation.

Headspace method can be used to quantify the most abundant volatile and non-volatile components. This combined with simultaneous distillation/extractions (SDE) gives the best qualitative view of the aroma profile of the food (Reineccius, 2006).

Sensory Testing Of The Aromatic Compounds

Sensory tests are often divided into 3 groups:

Discrimination/difference experiments

Descriptive experiments

Hedonic/affective experiments (Kilcast, 1999)

This is a very complex and complicated task. First, one needs to find a sample of chocolate that contains a universal “chocolate” flavour image most consumers accept. Then, it is necessary to isolate the compound or compounds that make up this image. The isolation of these various compounds is a major obstacle, since many of these are physically and chemically unstable.

In regards to chocolate, the main sensory analysis aside from aroma are:

melting character

effect of storage conditions

effect of compositional fat and substitution of fat

functionalization by adding other ingredients and its impact on sensory attributes

effect of the compositional content and structure such as sugar and fat or particle size on sensory properties

effect of different sensory methods on the chocolate product

The perception of taste, flavour, aroma, and texture in foods is complicated and dynamic, and how we perceive them can be different from moment to moment. The dynamic nature comes from the way in which we chew, salivate, breath, move our tongue, and swallow (Dijksterhuis, 1996).

Time-intensity sensory evaluation

Here the panelists will evaluate a specific sensory attribute over time, known as time-intensity (TI) sensory evaluation It is a helpful way to capture the dynamic nature of flavor and sensory attributes, instead of just a single-intensity evaluation (did it exist or not). Since these panelists are monitoring a perceived sensation from start to finish, the sensory analyst can quantify these perceptual changes. This offers are more vivid picture of the overall sensory experience of consuming the chocolate. This will have to be done for all the different sensory attributes the analyst would like to observe.

Temporal Dominance of Sensation

There is also Temporal Dominance of Sensation (TDS) which is a relatively new way to qualify the different sensations of food (Labbe, Schlich, Pineau, Gilbert, & Martin, 2009). In this, the panelists are asked to assess the dominate sensation during the evaluation method over time. Their results can be represented by curves that show how often each sensation was considered dominate throughout the tasting. It’s a quick and effective multi-attribute descriptive method. It allows many sensory attributes to be observed over the same timeline.

Conclusion

The flavour development in chocolate is associated with many aspects including the cacao growing conditions, the way the chocolate was processed, and ingredients. These impact the biological, chemical, and physical factors that impact the flavour. This can include fermentation to form precursors, drying to reduce acidity and astringency, Maillard reactions during roasting to create pyrazines and other aroma compounds, conching to determine the final flavour by isolating key odorants. The flavour of chocolate is the impact of all these factors and more coming together in the finished product.

Improving the flavour requires optimizing each step of the process, and being able to properly analyze the unique characteristics at each step as well.