Fermentation to reduce cadmium levels in cacao.

Fermentation used To Reduce Cadmium Levels In Cacao nibs

The following is a summary of the stated research mentioned above. The content summarized here, including the figures and tables, all belong to the researchers (unless otherwise indicated). The summary attempts to stay as close to the original paper as much as possible with some adjustments in regards to jargon, length, or to focus on bean to bar aspects.

Before We Begin

Cadmium in cacao

Cadmium (Cd) levels in cacao have become an issue with cacao predominately from South America. Many industry agencies, cacao distributors, and chocolate makers have made more of an effort to determine the levels of cadmium in their cacao sources and chocolate products.

Cadmium is a naturally occurring metal, and often extracted along with copper, zinc, and other metals. It can be found in foods such as shellfish, kidney meats, grains, and vegetables. It’s also found in cigarette smoke and emissions from fossil fuels. Exposure to high levels of cadmium can cause health issues such as chest pain, vomiting, diarrhea, and even kidney disease or increase bone fragility.

To read more about cadmium and related health concerns, please visit The Agency For Toxic Substances & Disease Registry.

Cacao bean fermentation

Figure 1. Anatomy of cacao and effect of fermentation on cadmium concentration.

The cacao fruit consists of an outer pod husk with 20-50 seeds (aka beans) inside. The seeds are surrounded by a sweet mucilage, and attached to a central tissue (cacao placenta). The seed consists of the seed coat or testa, and the cotyledons known as the nib.

These fruit covered seeds are required to go through a fermentation process, which is a necessary stage in chocolate production to build cocoa flavour. This process allows for the production of acetic acid bacteria and lactic acid bacteria, which in turn make the cacao very acidic. This increase in acidity also appears to decreases the nib pH from about a pH of 7 to as low as 4.5 post fermentation. Keep in mind, it is the nib which is used to make chocolate.

Overview Of The Research

The purpose of this work was to:

Analyze the levels of cadmium and their distribution between 5 different components of cacao, including the:

Outer pod husk

Mucilage (AKA pulp, AKA the fruit)

Placenta (The part of the fruit which attaches it together)

Nibs (The kernel of the seed, used to make chocolate)

Testa (The outer seed husk, disposed during chocolate making)

Investigate the influence of fermentation on cadmium distribution between these different cacao tissues. This would help better understand the how to lower Cd concentration via frementation.

Essentially, the fermentation process in this experiment resulted in cadmium (Cd) to migrate out from the nibs and into the testa during fermentation. The nib is what is used to make chocolate, and the testa is discarded as waste. Therefore, after this specific fermentation treatment the nib would contain lower levels of cadmium, and therefore result in chocolate with lower cadmium levels as well.

However, a key point from this study to remember is this migration of cadmium from the nib to the testa only occurred if the fermentation heap was quite acidic, at a pH of 5.0 or lower. This high level of acidity is what likely allowed the Cd to migrate out from the nib and collect in the testa. However, high levels of acidity in cacao is unfavorable, as it results in highly acidic chocolate.

Previous Research leading to this paper

In Jan. 2019, the European Commission approved a threshold limit for Cd in cacao-derived products. The new Cd level requirements in chocolate is 0.60 mg Cd per kg. This directly impacts South American cacao and South American cacao farmers since levels of Cd can be quite high in some regions here. Research by Bertoldi et al. (2016) stated Cd concentrations in some SA cacao were more than tenfold larger than in West-African cacao.

For this reason, researchers focused on ways to determine and limit levels of Cd in cacao beans. Much of this was directed at the soil, and they did find a relationship between Cd in soil and in cacao beans in Ecuador.

A survey by Vanderschuren et al. (2019) showed that Cd concentrations in cacao-derived products was related to their cacao content. So, cocoa powder containing goods with higher amounts of cacao, or higher percentage dark chocolate had higher levels of cadmium. This helped confirm that the Cd came from the cacao nibs rather than other ingredients that may have been contaminated in the process. These results were reported by others as well.

Some prior research has shown higher concentrations of cadmium in the testa compared to the nib. On the contrary, other research has shown just the opposite. However, the cacao in this research didn’t include much information into how they were processed and cured (such as whether they were washed or not, and parameters during fermentation such as temperature and pH levels). The influence of fermentation on Cd distribution hasn’t been reported until now.

Thyssen et al (2018) found elevated levels of Cd, Cu, K, Mg, Na, Pb and Zn in the testa versus the nib, but they didn’t look at levels of unfermented cacao samples. Zhai et al. (2019) reported Cd removal of up to 90% for rice fermented with lactic acid bacteria. The researchers here decided to study the similar impact on fermenting cacao beans.

Materials and Methods

Table 1

Ripe cacao fruits were collected from various locations in Ecuador. For the experiment, cacao was collected from Esmeraldas, El oro, Guyayas, and Sucumbios. The cultivars used were CCN51 and Nacional.

Fermentation:

Three methods of fermentation were used:

Cascade (batches A and B)

Fermentations were performed in cascades of 3 wooden boxes, measuring 60 cm x 60 cm x 60 cm, and the fermentation mass was mixed every 2 days by depositing them in the next box of the cascade.

Single Box (batch C)

Fermented in a single box, for which the cacao remained for the duration of the fermentation.

Single Box with pre-drying (batch Cbis)

Fermented as above, however, the cacao was pre-dried overnight before the fermentation process. This is a common practice to reduce excessive acidity development during fermentation.

REsults

Distribution of cadmium in unfermented cacao beans

Table 2. Samples of various tissues and their average cadmium concentration before being fermented. “N” represents the number of tests taken for each batch.

In the unfermented cacao samples, Batch D (Nacional cultivar from the Sucumbios region) had the greatest amount of cadmium, followed by batch C (Nacional from Guayas), and then Batches A (CCN 51 from El Oro) and B (Nacional from Guayas) with the least amount of cadmium. Batch D had levels nearly 7 times higher than in batch C.

Overall Cd concentrations in order from highest to lowest were in the:

Testa (greatest concentration)

Nibs

Placenta and Outer Pod Husks

Mucilage (lowest concentration)

It’s important to note that other studies found different results. For example, Ramtahal et al. (2016) found higher cadmium concentrations in the pod rusks compared to the nibs for farms in Trinidad and Tobago.

In this study, testa Cd concentrations were higher than nib Cd concentrations in all batches. The ratio for testa Cd to nib Cd in this study were:

A: 1.8

B: 1.7

C: 1.5

D: 1.7

One should also note that Ramtahal et al. (2016), Lewis et al. (2018), and Lee & Low (1985) also found higher Cd concentrations in the testa compared to the nib. However, Chavez et al. (2015) sampled cacao in Ecuador and found higher levels of Cd in the nibs compared to the testa. Keep in mind though, that in the Chavez et al. study, they washed the cacao beans with a hypochlorite solution before testing, which may have removed some cadmium in the outer testa.

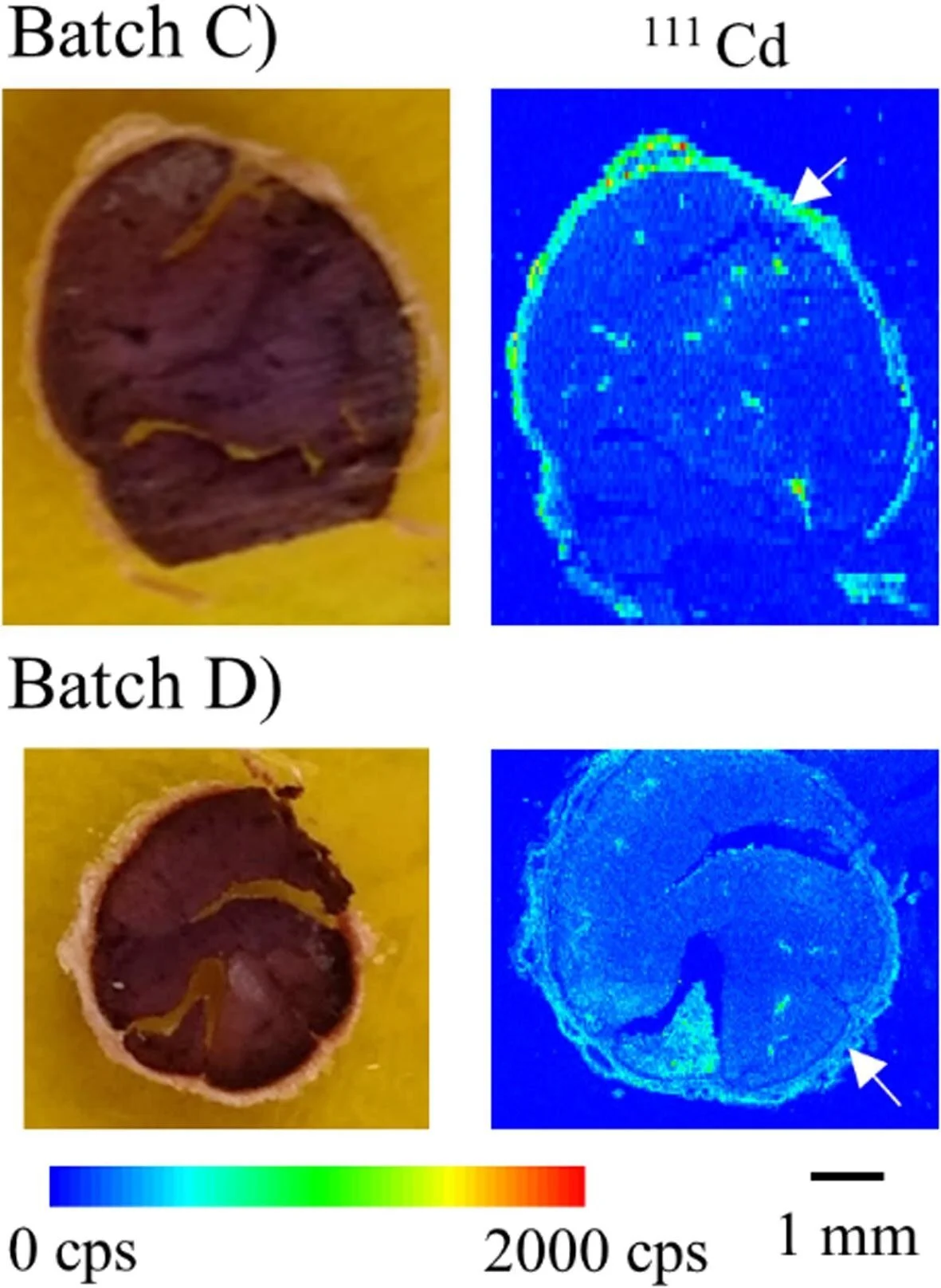

Figure 2. Visualization of the cadmium in the cacao. The white arrows point to the testa.

The Cadmium within the cacao beans from batches C and D were visualized using laser ablation inductivity together with plasma spectrometry (LA-ICP-MS).

The first photos on the left depict cross sections of cacao beans before using LA-ICP-MS. Both these samples are of unfermented cacao.

The cadmium concentration in batch C was 1.7 mg kg-1 in the nib and 3.1 mg kg-1 in the testa. The cadmium concentration in batch D was 11 mg kg-1 in the nib and 22 mg kg-1 in the testa. You can see this visually, especially in Batch C, where the bright turquoise representing the high concentration of cadmium in the outer testa encircling the nib.

It’s important to note, that right image from batch C used a larger laser beam at a faster speed than the bottom right image in batch D. This may be why the Cd is more clearly highlighted in the top right image.

Speciation of cadmium in unfermented cacao

Cd was found to be bound to O/N-ligands. In one, Cd was bound to amino and carboxyl groups (Cd-histidine) and in the other Cd was bound to alcohol and carboxyl groups (Cd-citrate). You can see the proportions the ligands were found in Figure 2 below. Different batches contained different ratios of the ligands of which the cadmium was bound.

Figure 2 Representation of Cd concentrations and the ratio of ligands they existed in within the samples.

Distribution of cadmium in fermented cacao

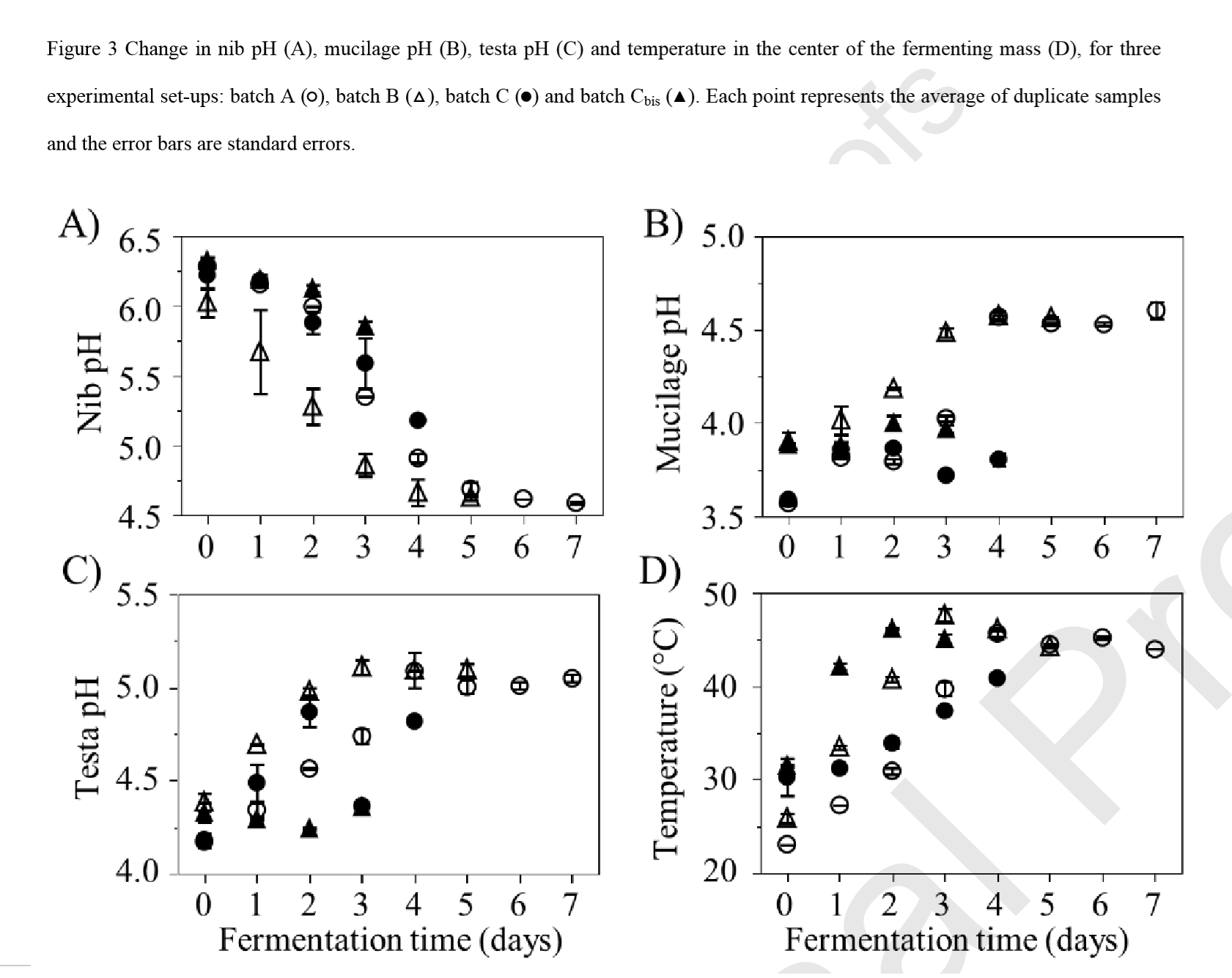

Figure 3. Changes in pH and temperature during fermentation of each of the four batches.

Figure 5. Nib pH concentration versus nib cadmium concentration. A (open circle), B, (open triangle), C (closed circle), and Cbis (closed triangle). Batches A and B both correlate, where batches C and Cbis do not.

Nib pH in batches A and B decreased (became more acidic) much more than in batches C and Cbis (Cbis the batch where the beans were pre-dried before fermenting). It’s important to note that fermentation time for C and Cbis batches were shorter (3-4 days) than for batches A and B (5-7 days). The longer fermentation time helps contribute to greater acid build up, which seems to be key in helping the Cd migrate out from the cacao nib. As well, nib Cd concentration was strongly tied to nib PH in Batches A and B. However, this wasn’t true for batches C and Cbis, which may further the idea of the necessity for a longer fermentation in order to get a lower pH, which then will induce cadmium migration out of the nib.

A pilot scale fermentation (5kg) using the same cacao from batches C, but fermented for a longer time, did show a greater decrease in Cd concentration in the nib, reinforcing the idea of fermentation time/acidity and decrease in nib pH.

A study on rice by Zhai et al. (2019) also observed a reduction in Cd concentration related to acid production during its fermentation.

Nib pH in batches A and B decreased from 6.2 to 4.5, mucilage pH increased from 3.7 to 4.5, and testa pH increased from 4.3 to 5.0. Fermentation was 5-7.

At the end of fermentation for batches A and B, the Cd in the nibs dropped from about 91% to 80%, and increased in the testa from about 9% to 20%. The results suggest that Cd migrates out from the cacao nib (kernel) to the testa and mucilage (fruit) during fermentation. This pushes the Cd into the tissues that get discarded, and lower the amounts in the tissue that goes on to make chocolate. You can compare levels of the various tissues in the figure 4 a-d below.

Figure 4a: Solid circle = Nib, Empty circle = Mucilage, Triangle = Testa.

Figure 4b: Solid circle = Nib, Empty circle = Mucilage, Triangle = Testa.

Figure 4c: Solid circle = Nib, Empty circle = Mucilage, Triangle = Testa.

Figure 4d: Solid circle = Nib, Empty circle = Mucilage, Triangle = Testa. Note no cadmium loss in the nib for this batch.

Overall, Batches A, B, and C showed a 15% reduction in cadmium by the end of fermentation. Batch Cbis, which was pre-dried, saw no Cd loss in the nib or testa. One suggestion for this is that the liquid in the mucilage runs off and evaporates (sweating) during fermentation, perhaps carrying Cd with it. With the pre-drying, which removes up to 25% of the liquid, there is less sweating that occurs.

Other elements

Generally, what has been true for cadmium, was also more or less true for other elements analyzed by ICP-MS including Al, As, Ca, Co, Cr, Cu, K, Mg, Mn, Mo, Ni, P, Pb, and Zn. Decreases were mostly only from batches A and B, not C and Cbis.

The nib concentrations decreased, and testa concentration increased, batches A and B for:

Copper

Potassium

Mg

Mn

Ni

P

Calcium was the only element that displayed a reverse change in concentration, where nib concentration increased while testa concentration decreased with fermentation time.

As far as batches C and Cbis, the only interesting observation was that Ni increased significantly in batch Cbis (the batch with pre-drying). The authors note this importance due to the European Commission mentioning cacao based products as an important source for Ni (EFSA, 2015).

CONCLUSION

In unfermented cacao fruits, the cadmium concentration is highest in the testa (the husk covering the cacao seed), followed by nibs, then placenta and husk tied at third, and finally the mucilage (the fruit).

When cacao is fermented for longer periods, the pH of the mass drops below 5. When the cacao mass is acidic, it appears to have cadmium migrate away from the nib (kernel) of the seed and into the husk and mucilage. Since the mucilage and husks are not used in chocolate making, this technique allows for lower levels of cadmium in the final chocolate product.

After fermentation, the cacao nib Cd concentrations decreased by a factor of 1.3, which indicates that this fermentation technique may be useful to comply with new Cd level requirements of 0.60 mg Cd per kg. If unfermented cacao Cd concentrations are at least .78 mg Cd per kg or lower, then this method would help reduce it to more satisfactory levels.

Of course, more work is required to assess the full potential here of Cd migration. As well, bringing down the cacao pH (high acidity) during fermentation makes the cacao and resulting chocolate very acidic as well, which is not a desirable outcome. Therefore, there needs to be a balance between acidity levels to reduce Cd concentrations in the nib, while also not resulting in acidic flavoured chocolate.