Relationship of sensory and instrumental aroma measurements of dark chocolate as influenced by fermentation method, roasting, and conching conditions

The following is a summary of the stated research mentioned above. The content summarized here, including the figures and tables, all belong to the researchers (unless otherwise indicated). The summary attempts to stay as close to the original paper as much as possible with some adjustments in regards to jargon, length, or to focus on bean to bar aspects.

Introduction

The researchers wanted to investigate if there is a relationship between key odorants and perceived flavour of dark chocolate influenced by cocoa fermentation method, roasting, and conching conditions. The relationship was analyzed by using multivariate data analysis. This is a type of statistical analysis which looks at the data from multiple variables, and used in more complex data analysis, such as in this case when the outcome of the aroma of the chocolate is based on the many different variables of the processing technique. Of the 16 flavour attributes associated with the samples, 8 of them were significantly different (p<0.05). In addition to multivariate data analytical tools, Principal Component Anlsysi (PCA) and Partial Least Squares (PLS) were used to investigate the descriptive analysis and GC-O (Gas Chromatography - Olfactometry).

Roasting significantly reduced astringency in heap-fermented samples, but not so in the tray-fermented samples. Unconched samples rated higher for banana flavour than the conched samples.

Introduction

The processes of roasting and conching play an important role in flavour development, aside from the genotype/origin of the cocoa and fermentation/drying methods. Both roasting and conching bring the product to high temperatures which aid in evaporating undesirable compounds and also developing desirable ones. Both the temperature and duration can impact these processes (Ramli et al. 2006; Krysiak 2006; Counet et al. 2002). Fermentation also impacts which aromas are present and contribute to the final flavour of the chocolate (Owusu et al., 2008).

Image by @rodrigoflores_photo

Consuming dark chocolate in moderation has been reported to have associated health benefits (Wollgast and Ankalm 2000; Steinberg et al. 2003). Along with this, the flavour quality is also key in chocolate quality and consumer choice. Chocolate manufacturers use different roasting and conching temperatures/durations for different cocoa bean varieties and for different chocolate products to achieve different flavour attributes. A good understanding of the flavour of food involves relating the sensory perception of its flavour with its chemical components (Drake et al. 2007).

Multivariate data analytical tools have been used to find patterns and correlations within samples and variables for many foods including wine (Nobel and Ebeler, 2002), tomatoes (Berna et al., 2005; Lee et al. 1999), bread (Sabanis et al., 2009; Gambaro et al., 2002), cheese texture (Drake and Gerard, 1999), spaghetti (Martinez et al., 2007), and textural changes in chocolate (Andrae-Nightingale et al., 2009).

Keep in mind that a good correlation between instrumental aroma volatiles and sensory flavour attributes may not necessarily indicate a cause and effect relationship. This is because there may be other reasons for the correlation, however, it is an indication that both variables change in the same manner. For example, the presence of a high level of identified odorant may also be an indication of a high intensity of flavour with which it’s correlated.

In this study, a good correlation of particular flavour attributes associated with fermentation, roasting, and conching, might enable one to use those different processes to guide particular flavour characteristics.

The investigation here was carried out to determine the effect of fermentation, roasting, and conching on the flavour characteristics of dark chocolates. It is also to establish a relationship between key odorants and perceived flavour attributes of dark chocolates as influenced by these processes, using multivariate data analysis to see if the use of one variable can predict another. This will be a useful tool for quality control of chocolate product to yield products with more desirable attributes.

Materials and Methods

Dark chocolate formulation

Six samples of dark chocolate were made (by Toms Confectionery Group A/S chocolate factory in Ballerup, Denmark) and the sample code and corresponding conditions were as follows:

hr0c2: heat fermented, unroasted, conched at 80°C for 8 hrs. (A)

tr0c2: tray fermented, unroasted, conched at 80°C for 8 hrs. (B)

hr2c0: heap fermented, roasted at 120°C for 45 min., unconched (C)

tr2c0: tray fermented, roasted at 120°C for 45 min., unconched (D)

hr3c1: heap fermented, roasted at 150°C for 30 min., conched at 80°C for 6 hrs. (E)

tr3c1: tray fermented, roasted at 150°C for 30 min., conched at 80°C for 6 hrs. (F)

Beans were broken and de-shelled, and then nibs were roasted (or left unroasted) according to conditions. Nibs were then brought to room temperature after roasting and processed in a laboratory grinder (Spectral 10, Santha, US) to produce cocoa liquor. The mixture of cocoa liquor and sugar was then refined in a three-roll mill refiner to reduce particle size. The result was then conched (or not). At the end of conching, cocoa butter and lecithin was added. The chocolate was then tempered and molded into bars.

Quantitative descriptive analysis

The panel members for this evaluation had received previous training on chocolate evaluation, but were also given further training which involved developing descriptive words for the aroma and flavour of the chocolate samples. If the same descriptor was used for both aroma and flavour, then it was labeled as “a” for aroma or “f” for flavour, as seen in Table 1. This table shows the references agreed upon and used by the panel.

Each chocolate sample was coded with a 4-digit random number, and samples were presented in randomized order. Each sample was evaluated in duplicate. Room temperature water was used to cleanse the palate. Samples were processed using gas chromatography-mass spectrometry (GCMS) and gas chromatography-olfactometry (GS-O), and analyzed using an analysis of variance (ANOVA) and Turkey’s range test. Multivariate data analysis were used including principal component analysis (PCA) and partial least squares (PLS).

Results & Discussion

Quantitative descriptive analysis

There were twelve descriptive attributes used to describe the chocolate samples. Four were aroma, and twelve for flavour (Table 1). Interaction between judge-replicate was not statistically significant meaning replications were not a source of error in any of these evaluated attributes. Interaction between sample-judge was also not statistically significant for any of the attributes except for fruity and astringent (the judges did not agree on the order of intensities of these two attributes). It has been reported (Misnawi et al., 2004) that people confuse astringency and bitterness since they do not understand the difference, and also because the two often go hand-in-hand even though they are different sensations. Many tannins and polyphenols, which are found in cocoa, exhibit both astringent and bitter sensations.

Eight of the twelve attributes were significantly (p<0.05) different intensities across samples including: yoghurt a, fruit a, banana, musty, prune/raisins, sweet, smoked, and astringent. Table 2 displays the differences across samples for these eight attributes.

The unconched tray sample (D) had a significantly higher value for fruit attribute than the unroasted conched tray and heap samples (A & B). Banana was higher in the unconched samples (C &D), which suggests that conching may have reduced this flavour attribute in the chocolate.

The unconched tray sample (D) was higher in smoked flavour than the other samples. The roasted conched tray sample (F) had a higher value of smoked than the corresponding heap sample (E). Since the unroasted tray sample (B) had a higher smoked flavour value than the unroasted heap sample (A), we can assume that this smoked off-flavour came from the tray fermentation rather than from the roasting.

The unroasted tray sample (B) was rated higher for musty than the unroasted heap sample (A) and the roasted conched heap sample (E). There was no difference between the two unconched samples (C & D) in regards to the musty flavour. This flavour is likely a result of mold contamination of the cocoa beans used (Dimick and Hoskin 1999; Misnawi et al., 2003).

The authors here suggest that the tray fermented beans used in this experiment were of poorer quality than the ones used by previous authors (Allison and Kenten 1963; Owusu et al., 2008). This indicates that if tray fermentation is properly carried out it would have likely resulted in cocoa beans with very good flavour.

The unroasted heap sample (A) scored higher in astringent mouth-feel than the roasted heap samples (C & E), which indicates the roasting reduced the perception of the astringent mouth-feel in heap samples. Although the astringency was reduced in the roasted tray samples (D & F), the difference was not significant. Cocoa polyphenol and flavonoids are associated with bitterness and astringency in cocoa, but fermentation, drying, and roasting reduces these levels (Porter et al., 1991; Bonvehi and Coll, 1997; Wollgast and Anklam, 2000a). Roasting oxidizes the residual polyphenols to quinones which are known to be very reactive agents (Heinzler and Eichner, 1991; Ziegleder, 1991; Katternberg and Kemmink, 1993). It’s also possible that polyphenols react with amino acids and proteins or polymerize with each other to form tannins (Misnawi et al., 2004). According to Misnawi, roasting reduces the ability of polyphenols to interact with proteins and causes a decrease in astringency. The authors also suggest that there is a possible alteration of polyphenols during the manufacturing process which involves high temperatures and the presence of oxygen (such as in conching). In this study, there was no significant difference in astringency between the unconched tray sample (D) and roasted conched tray sample (F). This observed difference between the two may be due to higher roasting temperature of sample F.

PCA of Sensory Data

A PCA bi-plot (Fig. 1) were done to visualize the relationships within the samples and the sensory attributes and how variations in the attributes explain variations in the samples. The two unconched samples (C & D) and the unroasted tray sample (B) had positive values of PC1, while the two roasted and conched samples (E & F) and unroasted heap sample (A) had negative values. The two unconched samples (C & D) had a musty, smoked, fruit, and banana aromas along with a musty and smoked flavour. This indicates that conching reduced the musty and smokey off-flavours as well as the fruit flavour in the chocolate samples.

Burnt, sour, coffee, and dark/porter beer were all closely correlated. Astringent mouthfeel, yoghurt flavour, and unripe fruit aroma were also correlated (while also related to the unroasted tray sample). This suggests that astringency in cocoa beans after fermentation and drying can be reduced with roasting of the cocoa beans.

Sweetness and astringency were on opposite sides of the PC1 axis, which means that the more astringent a sample is the less sweet it is perceived to be, likely because the astringency masks the sweetness. Lopez (1986) & Misnawi et al. (2004) also found an inverse correlation between astringency and sweetness.

GC-Olfactometry (GC-O) Data

Forty-six odorants were detected by the judges in the GC-O analysis and then identified by GC-MS (gas chromatography and mass spectrometry). This included odorants such as pyrazines, aldehydes, ketones, furans, and esters (results not shown). The GC-O data was used here to select the 16 most important aroma compounds relating to the chocolate samples.

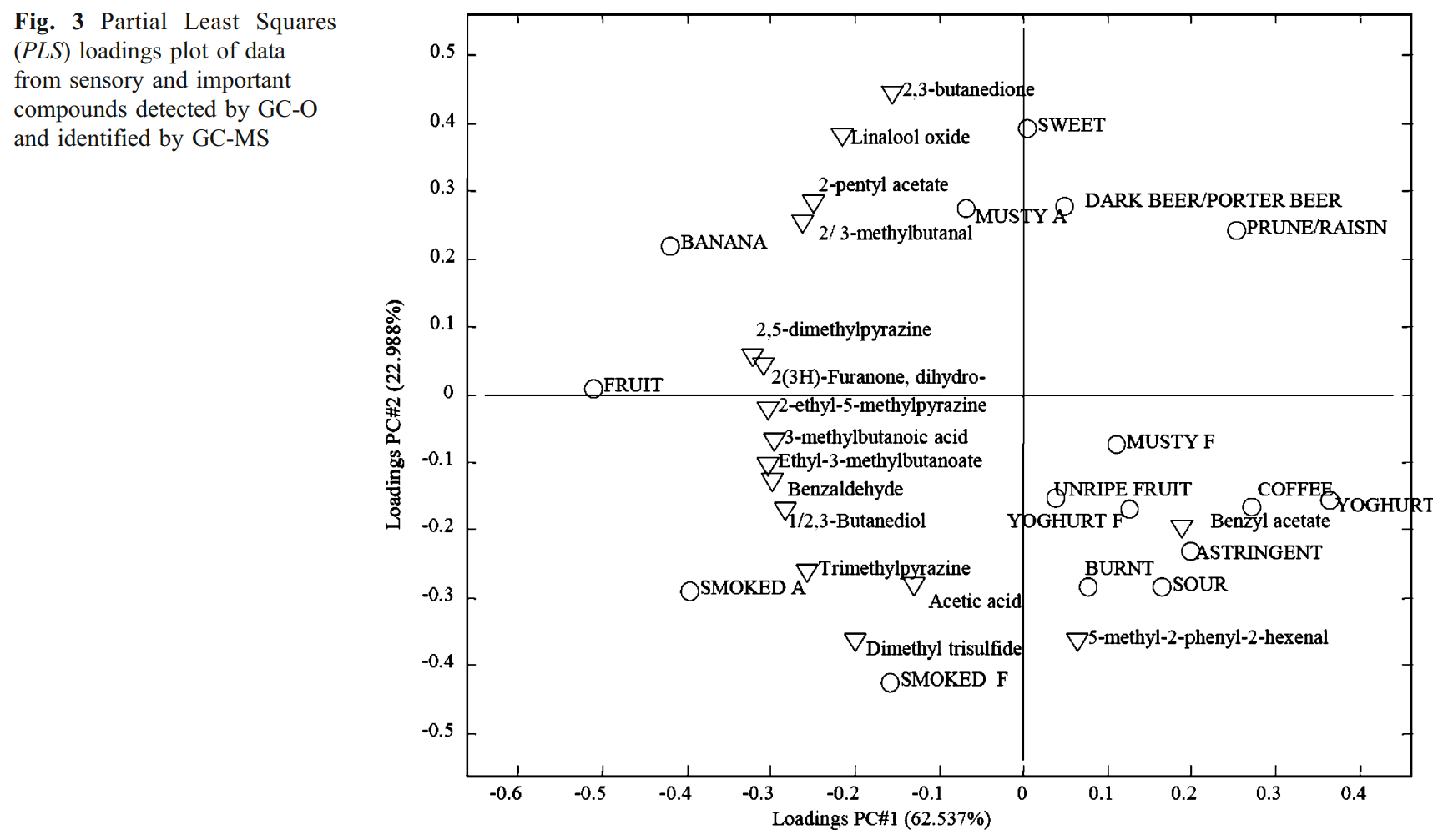

Partial Least Squares (PLS) regression models were used to correlated sensory data with instrumental data. Figures 2 and 3 show the scores and loading plots. PLS component one (PC#1) separated samples based on a combination of roasting and conching conditions. The conched samples had positive values and the unconched had negative values (Fig. 2). The PLS component two (PC#2) separated the unconched samples due to fermentation method. There was no clear separation of the other samples (conched) based on fermentation method.

The most important components had the highest concentration in the unconched samples (C & D - see Fig. 3). This indicates that the conching reduced the concentrations of most of these compounds. The concentrations of some were expected to increase with higher roasting temperature (particularly 2,5-dimethylpyrazine, 2-ethyl-5-methylpyrazine, and 2/3-methylbutanal). The unroasted samples conched for 8 hours had the lowest concentrations of most of the compounds. Conched samples had the highest levels of benzyl acetate and 5-methyl-2-phenyl-2-hexenal. This indicates that their concentration might have increased during the conching at 80°C for 6-8 hours. Fruit and banana flavours were positively correlated with 2,3-butandione (sweet, buttery), linalool oxide, pentyl acetate (green, cucumber), 2/3-methylbutanal (cocoa, roasted), 2,5-dimethylprazine (popcorn) and dihydro-2(3H)-furanone. These were negatively correlated with benzyl acetate (flowery) and 5-methyl-2-phenyl-2-hexenal (sweet, roasted cocoa). Smoked aroma and smoked taste had a positive correlation with 2,3,5-trimethylpryazine (fried potato), 2-ethyl-5-methylpyrazine (roasted, coffee), and dimethyl trisulfide (rubbery, onion), among others.

All 16 attributes were calculated against a single Y variable, which was fruit in this case (Fig. 4). Fruit attribute was highly correlated with ethyl-3-methylbutanoate (fruity, flowery); 2,5-dimethylpryazine (popcorn), dihydro-2(3H)-furanone (sweet); linalool oxide (sweet, flowery); benzaldehyde (earthy, nutty), and 2/3-methylbutanal (cocoa, roasted).

Figure 5 displays another model that indicate these compounds can be used to predict fruitiness in the chocolate samples.

Three important compounds had high correlation to astringent mouth-feel; 5-methyl-2-phenyl-2-hexenal was positively correlated while ethyl-3-methylbutanoate and pentylacetate were negatively correlated with astringent. Figure 6 is based on these compounds. A high concentration of 5-methyl-2-phenyl-2-hexenal can be predicted to also mean a high perception of the astringent mouthfeel. On the other hand, ethyl-3-methlbutanoate and pentyl acetate can be predicted to mean low astringent mouthfeel and vice versa. The astringent mouthfeel in chocolate is caused by polyphenols which are not aroma compounds, however, it may still be possible to predict this taste sensory attribute from the concentrations of these three aroma compounds. The concentration of polyphenols in cocoa and chocolate is related to fermentation and roasting (Porter et al., 1991; Clapperton et al., 1992; Bonvehi and Coll, 1997).

Conclusion

The correlation of sensory and aroma data using multivariate tools offer a model which can be used to indicate fruit attributes in dark chocolate samples processed in different ways. Since this fruity attribute was higher in unconched samples, it may be possible to determine if a chocolate is conched or unconched by the concentrations of the important compounds as discussed in this study. It was also possible to correlate astringency with 3 important aroma compounds, and so these compounds can be used to indicate if a sample is roasted or not.